Modular Biogas to Biomethane Plants

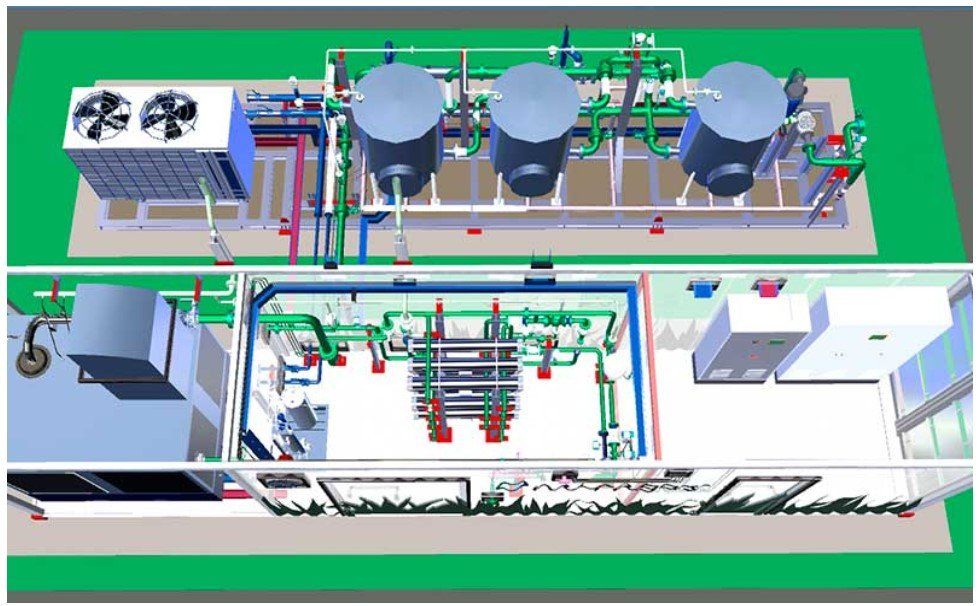

Biogas to Biomethane Upgrading Plants Are Made Up Of Two Containerized Modules. They can be shipped worldwide.

MODULE 1 : Pretreatment skid. This includes the activated carbon filters, heat exchangers, condensers, chillers and a blower. This is a pre-treatment area in which water, hydrogen sulfide and other existing traces of volatile organic compounds are eliminated from the Biogas.

MODULE 2 : CO2 compression and cleaning. This includes a screw compressor with oil removal, three membrane stages and all of the instrumentation for biomethane quality control. The biogas is compressed to 16 bar and using membrane technology the CO2 is separated creating a high quality biomethane.

| Component | Biogas % | Upgraded % |

|---|---|---|

| Methane | 50 to 70 | Over 95 |

| Carbon Dioxide | 25 to 50 | Less Than 2 |

| Nitrogen | 1.0 | 1.5 |

| Hydrogen | 0 to 1.0 | PPM |

| Hydrogen sulfide | 0.1 to 0.5 | PPM |

| Oxygen | 0 to 0.5 | PPM |

| Water | 3.0 to 4.0 | Less Than 1 PPM |

The plants use globally recognized Evonik membranes. Evonik membranes have the highest CO2/CH4 selectivity and are perfect for upgrading biogas. This selectivity of the membranes enables the production of high purity biomethane with superior methane recovery. The plants comply with the UNE-EN 16723-1 specification for injection into the natural gas network as well as the UNE-EN 16723-2 specification for use vehicle fuel.

| TECHNICAL DATA | Series 50 | Series 150 | Series 250 | Series 400 | Series 600 |

|---|---|---|---|---|---|

| Biogas Input flow [Nm3 / h] | 50 | 150 | 250 | 400 | 600 |

| Minimal Biogas Input flow [Nm3 / h] | 30 | 95 | 145 | 240 | 360 |

| BioMethane production flow [Nm3 / h] | 34 | 102 | 168 | 272 | 408 |

| BioMethane Pressure [Bar-a] | 16 | 16 | 16 | 16 | 16 |

| BioMethane Temperature [C] | 25 | 25 | 25 | 25 | 25 |